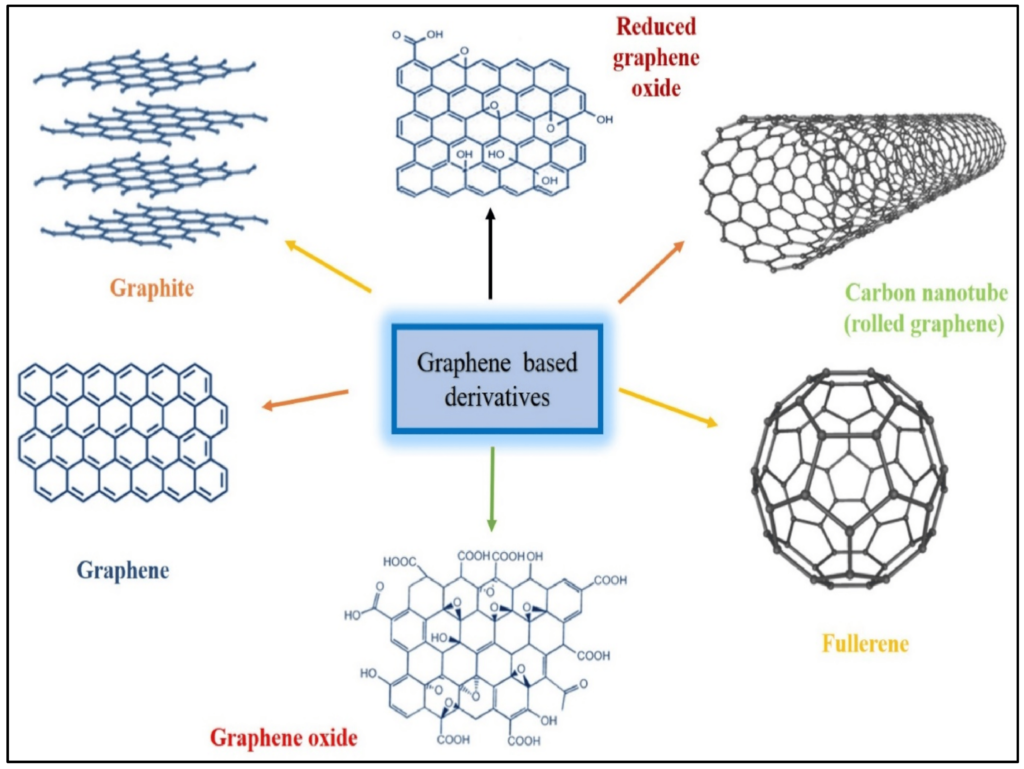

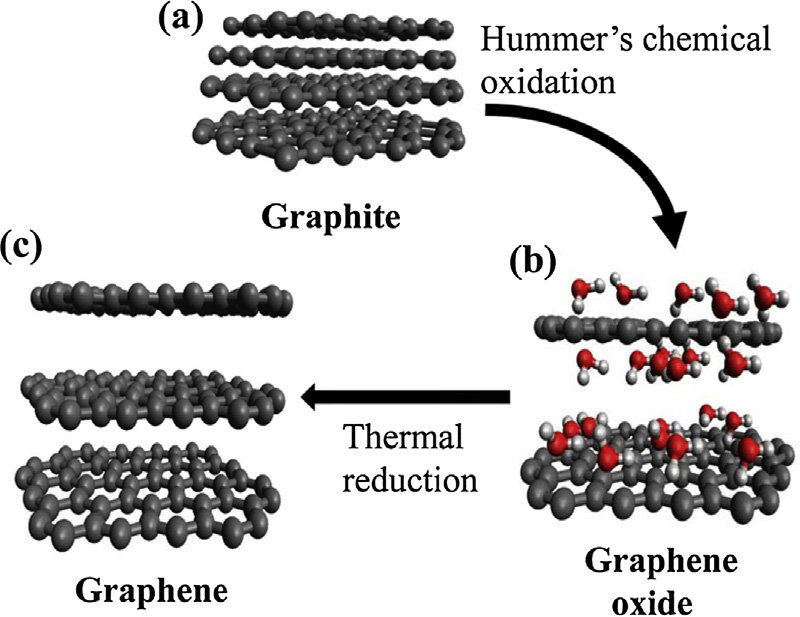

Graphene is incredibly strong, lightweight and an excellent conductor of electricity and heat, which makes it a highly promising material for various applications in electronics, energy storage, sensors, and more. Graphene is not a metal with a single layer of carbon atoms arranged in a hexagonal lattice. It is a basic structural element of other carbon allotropes like graphite, carbon nanotubes and fullerenes.

The unique properties of Graphene arise from the strong covalent bonds between carbon atoms and the hexagonal lattice structure. Despite being incredibly thin (only one atom thick), graphene is remarkably strong and flexible. Its electrical conductivity and high thermal conductivity are exceptional, making it a valuable material for electronic devices and for applications where efficient heat transfer is crucial.

Advantages of Graphene

Research into graphene is ongoing and scientists continue to explore its potential applications in various fields. Graphene possesses several remarkable properties, leading to numerous potential advantages and applications across various fields. Some of the main advantages of graphene are

Very High Strength

Graphene is incredibly strong and can withstand a great amount of force despite being only one atom thick. It is stronger than steel, making it ideal for structural applications.

Very High Electrical and Thermal Conductivity

Graphene is an excellent conductor of electricity, allowing for efficient electron mobility. This property is crucial for applications in electronics and nanotechnology. Graphene also exhibits excellent thermal conductivity, making it an efficient heat conductor. This property is valuable in various thermal management applications, including in electronics and aerospace.

Flexibility and Lightweight

Despite its strength, graphene is also extremely flexible. It can be stretched and bent without losing its properties, making it suitable for flexible electronics and wearable devices. Graphene is one of the lightest materials known, which is advantageous in applications where weight reduction is critical, such as in the aerospace and automotive industries.

Impermeable but Transparent to Light

Graphene is impermeable to gases and liquids, even helium atoms cannot pass through it. This property has applications in creating efficient barriers and membranes. Graphene is transparent, allowing light to pass through. This property is useful in applications such as transparent conductive films for touch screens and solar cells.

Biocompatibility

Graphene exhibits biocompatibility, making it suitable for various biomedical applications, including drug delivery, tissue engineering and bio-sensors. This property helps explore applications of mounting or blending wearable sensors to skin permanently.

Efficient Cells and Batteries

Graphene-based materials can potentially enhance energy storage devices (batteries and super-capacitors) and improve the efficiency of solar cells.

Better Composites

Graphene can be mixed and combined with other materials to create composites with specific properties, expanding its range of applications.

Aerospace and Military Applications

Graphene’s unique properties make it a promising material for various aerospace and military applications. A few of them are given below

Lightweight and Strong Aerospace Components

Graphene’s exceptional strength-to-weight ratio makes it an ideal candidate for manufacturing lightweight and strong components for aircraft and spacecraft, leading to reduced overall weight and improved fuel efficiency.

Aircraft and Satellite Structures

Graphene composites can be used in the production of structural materials for aircraft, making them lighter, stronger, and more resistant to wear and tear.

Heat Management

Graphene’s high thermal conductivity can be utilized for improving the heat management systems in spacecraft and aircraft. It can enhance the efficiency of thermal control systems, ensuring that electronic components and sensitive instruments remain within optimal temperature ranges.

Lightweight Battery and Fuel Cells

Graphene-based supercapacitors and batteries can store and deliver energy efficiently. These lightweight energy storage solutions are crucial for aerospace applications, where saving weight is a top priority. Graphene-based materials can enhance the efficiency of fuel cells, which could be used in aerospace applications for providing power to aircraft systems and instruments for long hours. Graphene-based supercapacitors and batteries are very valuable for military applications, powering everything from soldiers’ equipment to unmanned aerial vehicles (UAVs).

Airborne Antennae

Graphene-based antennas could significantly improve communication systems in aircraft and satellites due to their excellent electrical conductivity and flexibility. These antennas could be more efficient and lighter than traditional ones.

EMI Proof

Graphene composites can be used for electromagnetic interference (EMI) shielding in aerospace applications. EMI shielding is essential to protect sensitive electronics from interference and Graphene’s conductivity properties make it an excellent candidate for this purpose.

Airborne Sensors

Graphene-based sensors can be employed for various purposes, including detecting strain, pressure, and temperature changes. These sensors are crucial for monitoring the structural integrity of aircraft and spacecraft.

Aircraft Anti-Icing Technology

Graphene coatings can be used to create anti-icing surfaces. By applying a thin layer of graphene, it’s possible to prevent ice formation on critical surfaces of aircraft, ensuring safe operation in icy conditions.

Spacecraft Thermal Insulation

Graphene aerogels, which are highly porous and lightweight materials, can be used as thermal insulators for spacecraft. They provide effective thermal insulation without adding much weight.

Lightweight, Strong Armour and Ballistic Protection

Graphene’s exceptional strength and lightweight nature make it suitable for developing advanced body armour and vehicle armour, providing better protection to soldiers and military vehicles while reducing their overall weight. Graphene composites can be incorporated into helmets, vests, and vehicle armour to enhance their resistance against bullets and shrapnel, improving the safety of military personnel.

Stealth Technology

Graphene-based materials can be used in stealth technology. Due to their unique electromagnetic properties, graphene coatings might absorb radar waves, making military aircraft and equipment less detectable by enemy radar systems. Graphene coatings can be also used to protect military equipment from corrosion and wear. Can also be used in adaptive camouflage systems, allowing military vehicles and uniforms to change their appearance in different environments.

Flexible Electronic Boards

Graphene’s flexibility and conductivity make it suitable for flexible electronics. This technology can be integrated into military uniforms and equipment, enabling features like flexible displays, sensors, and communication devices. We can mount PCBs on the clothes of soldiers/ aircrew.

Challenges

While graphene has numerous exceptional properties, there are also several challenges and limitations. Producing high-quality graphene in large quantities is still a significant challenge. Current production methods often result in small quantities of high-quality graphene, making mass production difficult and costly. The production of high-quality graphene can be expensive. As of now, producing graphene on a large scale remains costly, hindering its widespread commercial adoption.

Some production methods involve the use of chemicals and high energy, raising environmental concerns. Additionally, the disposal of graphene-based materials could pose environmental challenges if not managed properly. Modifying its properties for specific applications can be challenging and may affect its unique properties. Finding ways to functionalize graphene without significantly altering its structure is a complex task. Albeit the biocompatibility of graphene-based materials is a topic of concern. Research is ongoing to understand the potential health risks associated with the use of graphene, especially in biomedical applications.

A lack of standardized production processes and quality control measures can lead to inconsistencies in graphene quality, affecting its performance and reliability in various applications. Despite extensive research, there are still limited large-scale commercial applications for graphene. Transitioning from laboratory research to scalable industrial applications has been slower than anticipated. Graphene, when isolated as a single layer, is incredibly strong. However, in practical applications where it needs to be combined with other materials, its strength might not always be fully utilized, and it can be more fragile than expected. Albeit graphene has a zero band gap, which means it behaves as a conductor, not a semiconductor. This property limits its direct use in digital electronic applications where a distinct on-off behaviour is required. Graphene degrades in the presence of certain gases, limiting its use in environments where exposure to such gases is inevitable.

Conclusion

It’s important to note that while these applications show much promise, many are still in the research and development stage. Additionally, the mass production of high-quality graphene and graphene-based products at a cost-effective scale is a challenge that needs to be addressed for widespread military adoption and for the aerospace industry. Military applications of graphene continue to be an area of active research and innovation. Researchers and scientists are actively working to overcome these challenges through ongoing research and development efforts, aiming to unlock the full potential of graphene while addressing its limitations. Ongoing research and development efforts continue to explore the full potential of graphene in aerospace applications. The development and commercialization of graphene-based products might face regulatory challenges, especially in sectors such as healthcare and consumer products, where safety standards are stringent.

Disclaimer: The views and opinions expressed by the author do not necessarily reflect the views of the Government of India and Defence Research and Studies

Image Courtesy: The Hans India