Pulse Detonation Engines are economical and can revolutionise the power plants of military and civil aircraft.

With rapid technological advances in propulsion technology, the gamut of aerospace propulsion is undergoing a sea change. These days the rocket engines (air-breathers) are being used for aerospace propulsion purposes, but these are less efficient. Thus efforts are in hand to find viable efficient alternatives for these.

Pulse Detonation Engine (PDE) is one such efficient engine that can replace rocket engines. Many countries including India are working on PDEs, the future of aerospace propulsion.

This article will, therefore, examine concepts of the Pulse Detonation Engines, their functioning, recent advances, befits and problems related to PDEs, their future and current scenarios in India and Russia.

Concepts of Pulse Detonation Engines (PDE)

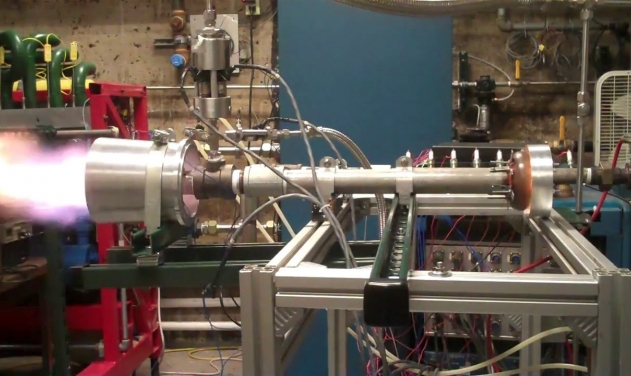

The Pulse Detonation Engines (PDEs) is being developed on an experimental basis (as of now) as propulsive devices that use supersonic detonation waves as a combustion mechanism. In theory, the PDEs offer numerous advantages over traditional gas turbine engines, including improved efficiency and reduced mechanical complexity. However, the concept has not matured yet and PDE designs still need to overcome significant hurdles in order to become a viable and efficient form of propulsion- which just a matter of time as research into PDE designs, engineering properties and potential is ongoing.

Traditional Gas Turbine Engines Vs Pulse Detonation Engines

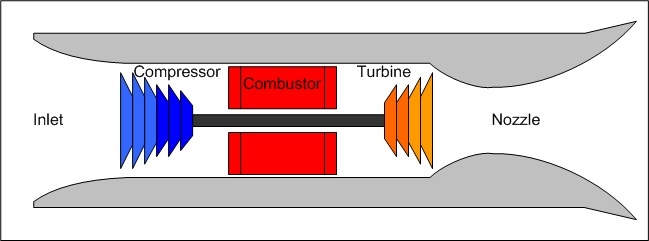

In conventional jet engines (Fig-2), the air is compressed by means of a compressor and then mixed with fuel before the combustion stage, where the combustion is generally a subsonic process. The hot gases then drive a turbine, and in turn the compressor, before being accelerated through a nozzle thereby producing thrust. The turbine engines cannot start from rest by themselves and require the use of a starter to get them to self-sustaining speeds. Conventional Jet engines follow the Brayton cycle, which requires the compression of air to high pressures before heat release is possible, thereby requiring the heavy compressor and turbine mechanisms.

In comparison, the Pulse Detonation Engines (PDEs) can operate theoretically from a standstill state up to a Mach number of 5. PDEs do not require heavy compressors, thereby reducing the overall weight and complexity of the engine. The geometry of PDEs is also simple, consisting essentially of a tube with control valves for fluid delivery. The detonation process delivers higher pressures and temperatures from the reaction and offers better efficiencies.

The fundamental physics behind PDEs is rather simple. Combustion occurs in a shaft with valves or carefully crafted openings at each end so that gas can only pass one way through the device (Fig: 2 refer). The fuel mixture in the chamber is ignited in such a way that it combusts and expands supersonically (detonation), sending a shock wave down the length of the chamber. Because the shock wave moves so rapidly, the rest of the fuel in the engine combusts before it has time to expand; thus, combustion occurs at approximately constant volume. A constant-volume combustion process releases more chemical potential energy as heat than the constant-pressure process found in conventional turbine engines (Cassidy, 2016).

The PDEs offer higher specific impulses than rockets and conventional air-breathing engines at all Mach numbers. Therefore, there are studies underway seriously attempting to integrate pulsed detonation mode of combustion within rockets and scramjet engines, which could combine the advantage of the boost in performance achieved from the detonation process over the deflagration process* (*will be discussed later in the article).

PDEs essentially bridge the gap between the subsonic and the hypersonic regimes, after which scramjets and rockets take over. All of the above account for the explosion in the field of detonation and PDE research recently. This has led to the launch of several competing research programs with the aim of developing a working PDE system (ARC, 2014).

Difference between Detonation and Deflagration*

Detonation refers to the supersonic combustion process whereas deflagration is a subsonic combustion process. Almost all engines that burn fuel employ deflagration to release the energy contained within the fuels. In detonation, a shock wave compresses the gas which is then followed by the rapid release of heat and a sudden rise in pressure. As per Chapman-Jouguet theory, the detonation wave comprises a shock wave and a flame front. As the wavefront passes through the gas, the gas is compressed and the chemical reaction is completed at the rear of the wavefront. The detonation process is supposed to be more efficient than the deflagration (ARC ibid).

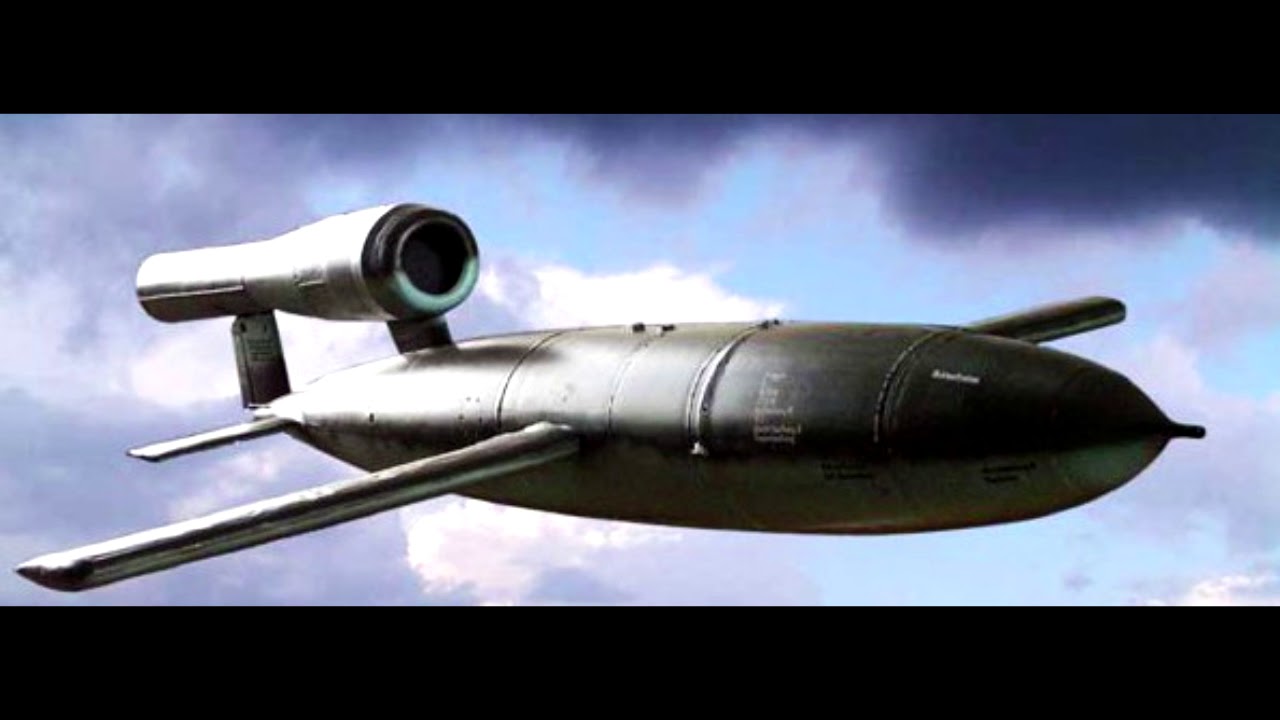

Historical Perspective- PDEs

Technologically, the Pulse Detonation Engines are the supersonic relatives of pulse-jet engines. Pulse- jets relied on intermittent, subsonic deflagration flames in a long tube to burn an injected fuel- oxidizer mixture. Pulse-jets emerged during World War II, as the propulsion system of the dreaded V-1 bombs. The performance of the pulse jets is limited by the constant pressure slow flame speed. In comparison, Detonation waves, a supersonic phenomenon, propagate at speeds in the thousands of meters per second, and can therefore be modelled as a constant volume process.

Serious research in the field of detonation propulsion systems began in the 1950s, at the University of Michigan. The novel idea of intermittent detonation gained traction in the 1980s as the Naval Postgraduate School (USA) investigated the design further. However, experimental work encountered a number of challenges, namely the difficulty with transitioning a subsonic deflagration wave (a flame) into a supersonic detonation wave, as well as properly mixing the fuel and oxidizer to produce a uniform detonation.

With the advancement in technology, the PDE concept has continued to garner academic research interest and PDE research is being attempted from a variety of angles, including computational fluid dynamics, experimental thermodynamics, as well as laser diagnostics. The prospects for PDEs are becoming brighter by the day (Cassidy, 2016a).

Recent Advances in PDE Technology

Many researchers working in the propulsion field have turned towards the pulse detonation engines, working with a combination of thermodynamics analysis, detonation initiation processes and deflagration to detonation wave transition devices as their main subject in the detonation combustion research area.

Research on rotating detonation engines and their application in aerospace turbomachinery and performance assessment is also being progressed. These involve researches from the United States (Pratt and Whitney), Russia (United Engines Corporation), Japan and China, Germany, and Malaysia (HiREF, Universiti Teknologi). India (DRDO) has made a beginning in the field. The numbers of research publications have also increased significantly in recent years, thus making more material for further work. Researchers are hopeful of making a breakthrough, making PDEs commercially viable in the coming years (Pandey and Debnath, 2016).

Benefits and Problems related to PDEs

Advantages

The simplicity of PDE’s design is its undeniable virtue. Further, as the fluid combustion proceeds in the shock waves about 100 times faster than in conventional slow combustion (deflagration), this type of engine is theoretically distinguished by record power per unit of volume compared to all other types of thermal engines. Apart from the high relative power the detonation engines potentially have other significant advantages. For example, during the cycle of detonation combustion is possible to achieve very high temperatures. But the combustion speed is also very high and nitrogen oxides do not have time to form, therefore the detonation engines are potentially environmentally friendly. The problem of cooling the combustion chamber is as well easier to solve. Despite the higher temperature and pressure in the detonation wavefront due to the transience of detonation combustion processes their impact on the engine’s structure is less than that of classical motors. Usage of detonation combustion provides tangible advantages in the Liquid Rocket Engines as well (Bulat, 2014)

Limitations

Despite many advantages PDEs offer over conventional turbojet engines, PDEs are still away from commercial applications. There many technological limitations which need to be overcome. Some of them are (Valli and Jindal, 2014):-

- One of the key barriers for an operational Pulse Detonation Engine lies in the difficulty to ignite the detonation wave in the engine in a reliable and controllable manner. This barrier is particularly critical for an application that involves hydrocarbon/air mixture. This is so because detonations are difficult to achieve within a practical length in hydrocarbon/air mixtures, which are less sensitive to detonation initiation.

- Another difficulty is in optimising the diameter of the detonation tube in a practical manner.

- As of now, the Lengths of detonation tube required are quite large.

- Cycle repetition frequency and Cell width are other issues which are creating barriers,

- Research is still going on the most suitable materials for the manufacture of the PDE components.

Despite above limitations constant researches are going on the field of PDEs because of the vast potential they hold. Researchers are quite optimistic about the breakthroughs which would allow commercial usage of PDEs.

Future outlook

Researchers feel that the pulse detonation engines have great potential to provide a significantly more efficient combustion cycle than deflagration-based engines. The application of this technology to turbines promises to increase the thermodynamic efficiency of these engines to previously unattainable levels.

The PDE- as a standalone engine also holds significant promise for both air-breathing and air-independent rocket propulsion, subject to further research on the following:-

- Nozzles have been shown to have limited benefit to the thrust generated by PDEs.

- Study of thrust to weight carrying out sufficient experimental work in vacuum conditions or microgravity conditions.

- Determination of maximum equivalence ratio at which an RDE will operate.

- Study on Triple points for determining the constraints, besides chemical composition.

- Research on a mathematical relationship between the detonation cell width and the geometry requirements of the chamber.

- Research on varying channel widths to determine what the optimal width would be for different design requirements.

- Research to determine an appropriate chamber length and correlation with efficiency.

It has been demonstrated that the thrust produced by PDEs scales non-linearly with engine size, but they are not yet approaching the size required to replace most existing gas turbines. With many researchers working in the PDE field, it has been anticipated that the limitations could be overcome and PDEs could be scaled up sufficiently to provide the thrust levels offered by contemporary gas turbine engines, in due course of time (Shaw et al, 2018).

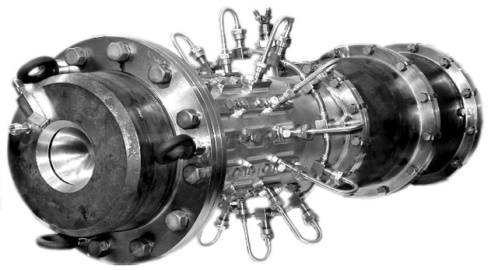

PDE developed by Russia

It has been reported that Russia’s United Engine Corporation (UEC) has completed the first stage of testing a pulse detonation engine, which in the future can be used in advanced rocket and space systems, hypersonic aircraft and orbital space-planes. In some operating modes, the power plant has demonstrated up to a 50% increase in specific thrust when compared to conventional engines. ROSTEC Aviation Cluster has stated the following in relation to the PDE tests:

The first stage of testing the pulse detonation engine demonstrator has been successfully completed. It has shown the required performance characteristics. In some operation modes, the specific thrust was up to 50% higher than the performance of traditional power plants. This will prospectively increase the maximum range and payload mass of aircraft by 1.3–1.5 times. The design will be able to be applied, for example, on orbital spaceplanes, supersonic and hypersonic aircraft, and future-generation rocket and space systems.

Russia feels that Aircraft equipped with pulse detonation engines will have better flight dynamics and manoeuvrability. The engine type can be used to develop traditional rocket and air-jet propulsion systems or their support systems (Indiadefencenews, 2021).

PDE by DRDO

It has been reported that India’s Defence Research and Development Organisation (DRDO) has developed a pulse detonation engine which has higher fuel efficiency than the gas turbine ones for cruise, anti-tank missile and unmanned aerial vehicles propulsion.

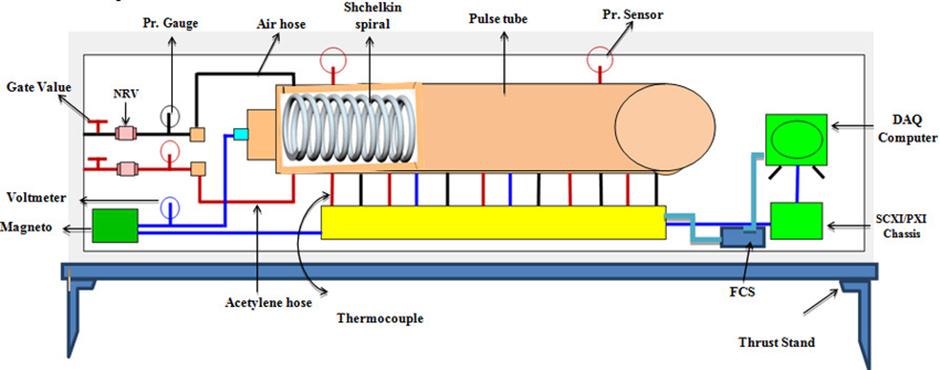

Post-tests on the basic engine, DRDO’s unit Terminal Ballistics Research Laboratory (TBRL) is currently working on an air-breathing multi-tube, multi-cycle pulse detonation engine. TBRL is working on an air-breathing multi-tube multi-cycle pulse detonation engine with an objective to develop an air-breathing Pulse Detonation Engine to generate 2.5 kN of thrust for a duration of 30 minutes.

As TBRL, for flying systems, detonation requires a long tube length to accommodate the required amount of energy input. TBRL has been working on a system to reduce the length of the engine so that it can be applied in systems like UAVs and other missiles system as well. A DRDP Paper on the subject pointed out that:

To reduce engine length, suitable devices are employed which reduce the length of the tube required for the transition from deflagration to detonation. A test rig was designed and established for conducting experiments with liquid fuel-air mixtures.

DRDO is hopeful of taking the research forward and achieving a breakthrough for providing PDE based equipment to Indian armed forces followed by commercial applications (defence world, 2017).

Conclusion

Technologically is has been anticipated that the PDEs would offer numerous advantages over current jet and rocket propulsion systems. But their practical development has met with numerous challenges, quite a few of which remain unsolved today.

PDE researchers feel that advances in this field have pushed the boundaries of engineering knowledge by fuelling the development of improved gas dynamic models and diagnostics while improving understanding of combustion science and fluid dynamics. They are hopeful of achieving the breakthrough to make PDEs both technologically and economically viable.

India (DRDO) has already taken the steps in this field and it is recommended that:-

- A serious thought may be given to the continuation of the research in the PDE field and sufficient funds may be allocated for the work.

- Though maybe given to building a synergetic approach with Russia to jointly develop technologically and financially viable PDEs. The Brahmos model may be considered for this project.

- Threat from China’s PDE program may be evaluated and parameters for research by DRDO be finalised based on the threat perception.

It is hoped that DRDO will rise to the occasion and make India Atmanirbhar in the field of Pulse Detonation Engines- a future of aerospace. Jai Hind.

Disclaimer: The views and opinions expressed by the author do not necessarily reflect the views of the Government of India and Defence Research and Studies

Title image courtesy: Youtube

References:

1, Cassidy Sean, 21 Nov 2016, Stanford University, Pulse Detonation Engines, Retrieved from: http://large.stanford.edu/courses/2016/ph240/cassady1/#:~:text=The%20Pulse%20Detonation%20Engine%20(PDE,efficiency%20and%20reduced%20mechanical%20complexity , Accessed on 10-11 Apr 2021

2. Aerodynamics Research Center, 2014, University of Taxa Arlington, Pulsed Detonation Engines, Retrieved from: https://arc.uta.edu/research/pde.htm, Accessed on 10-11 Apr 2021

3. Cassidy Sean, 21 Nov 2016a, Stanford University, Pulse Detonation Engines, Retrieved from: http://large.stanford.edu/courses/2016/ph240/cassady1/#:~:text=The%20Pulse%20Detonation%20Engine%20(PDE,efficiency%20and%20reduced%20mechanical%20complexity , Accessed on 10-11 Apr 2021

4. Pandey KM and Debnath Pinku Dr, Jan 2016, Researchgate (Article in Journal of Combustion), Review on Recent Advances in Pulse Detonation Engines (DOI: 10.1155/2016/4193034) Retrieved from: https://www.researchgate.net/publication/291205810_Review_on_Recent_Advances_in_Pulse_Detonation_Engines, accessed on 10-11 Apr 2021

5. Bulat Pavel Viktorovich, Aug 2014, Researchgate, About the Detonation Engines, DOI:10.3844/ajassp.2014.1357.1364), Retrieved from: https://www.researchgate.net/publication/263651647_About_the_detonation_engine

6. Valli DM and Jindal TK Dr, Apr 2014, Researchgate, Pulse Detonation Engine: Parameters Affecting Performance, Retrieved from: https://www.researchgate.net/publication/268740511_Pulse_Detonation_Engine_Parameters_Affecting_Performance, Accessed on 10-11 Apr 2021

7. Shaw Ian J, Kildare Jordan A C, Evans Michael J, Chinnici Alfonso, Sparks Ciaran AM, Rubaiyat Shekh N.H, Chin Rey C and Medwell, Paul R,23 Oct 2018, intechopen, A Theoretical Review of Rotating Detonation Engines (DOI: 10.5772/intechopen.90470) , Retrieved from: https://www.intechopen.com/books/direct-numerical-simulations-an-introduction-and-applications/a-theoretical-review-of-rotating-detonation-engines, Accessed on 10-11 Apr 2021

8. India Defence News, 10 Apr 2021, indiadefnecnews, RUSSIA’S DEMOS PULSE DETONATION ENGINE, Retrieved From: http://www.indiandefensenews.in/2021/04/russias-demos-pulse-detonation-engine.html , Accessed on 10-11 Apr 2021

9. Defence World, 20 May 2017, Defenceworld.net, India Develops Pulse Detonation Engine For Cruise, Anti-Tank Missiles, Retrieved from: https://www.defenseworld.net/news/19350/India_Develops_Pulse_Detonation_Engine_For_Cruise__Anti_Tank_Missiles#.YHLZTugzbIU, Accessed on 10-11 Apr 2021