The unleashing of COVID 19 on humanity has been an unprecedented catastrophe in recent times. Even if we go back in history, other pandemics would be a pale shadow to the present impact of this virus on the health and economies of all countries worldwide. This scourge has affected all of humanity, impacting lifestyles, businesses, economies and our common well being.

Even before the onset of this pandemic, the global economy was facing turbulence on account of disruptions in trade flow and growth. The present situation has now been escalated by the demand, supply and liquidity shocks which the COVID 19 has inflicted upon the entire industry. Once the pandemic is managed, the shape and speed of recovery of our economy will be the key factor for the further growth of the country.

Our Performance Manufacturing Index (PMI) went down to 38% in March 2020, hopefully, it is recovering now to 50.7%. Index for industrial production declined to 118.10 (contraction by 11.10%) in July 2020 with the industrial growth contracting by 29.2% as compared to a 3.5% rise in the same period last year. The contribution of our manufacturing sector to the GDP has been around 24%.

This has been despite India’s expanding economy and robust middle class which provided a lucrative market with its abundant skilled and semi-skilled labour adding to the country’s ability to support bulk manufacturing.

Considering the geopolitical situation today, we are beset with increasing national security issues which would involve productivity, skill development, labour intensive systems, infrastructure development and improvement in financial and credit facilities.

The story of the Indian defence industry has been quite pathetic. Despite several associated bodies and a huge workforce engaged in research, development and production, India continues to be the world’s second-largest arms importer. As per the Stockholm International Peace Research Institute (SIPRI) latest report, India accounted for almost 10 percent of the global volumes of arms imports in the last five years. In comparison, China accounts for 4.3 percent. Successive past attempts to reverse the fortunes of indigenous arms production have met with limited success. Past failures notwithstanding, one more attempt is currently being made by this government, through its ambitious “Make in India” programme. Under the programme, a host of initiatives have been taken/are being contemplated by the Ministry of Defence (MoD) with the objective of making India self-reliant in terms of defence requirements. The question that still looms large, however, is: can the new initiative change the fortune of an industry that has been marred thus far by a host of legacy issues? Issues such as policy conservatism, structural inadequacy, and gross inefficiency of the entities directly responsible for research and development (R&D) and production have been plaguing us for quite some time now.

Make in India has been a non-starter lacking policy focus. 25 varied sectors were projected mainly Automobiles/Components, Chemicals, IT, Pharma, Aviation, Electronics, Space etc. Along with this with much fanfare, other programmes like Skill India, Digital India and Startup India were announced. Thereafter, we were debating aspects like Make in India, Made in India and Make for India. The progress in all these programmes has been mostly dismal. India ranks low on the “ease of doing business index”. Labour laws in the country are still not conducive to the “Make in India” campaign. This is one of the universally noted disadvantages of manufacturing and investing in India. The Government has vowed to remove these hurdles and make the nation an ideal destination for investors to set up industries.

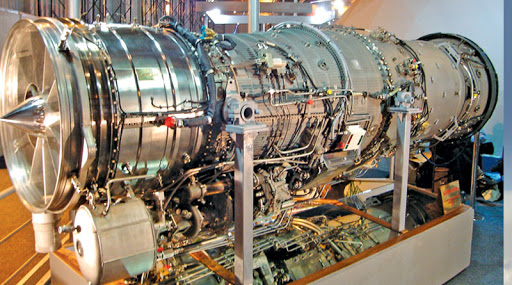

India allocates about 1.8% of its GDP towards defence spending, of which 40% is allocated to capital acquisitions and only about 30% of India’s equipment is manufactured in India, mainly by public sector undertakings. Even when defence products are manufactured domestically, there is a large import component. The Indian defence industry is largely dominated by government-owned/controlled entities; with the private sector playing a peripheral role. The dominance of the public sector is ensured through the nine giant Defence Public Sector Undertakings (DPSUs) and 41 Ordnance Factories (OFs) that are under the administrative control of the MoD’s Department of Defence Production (DDP). There are also 50-odd research laboratories under the umbrella of the Defence Research and Development Organisation (DRDO), the MoD’s premier R&D agency.

Together, these three (DPSUs, OFs and DRDO) have more than 190,000 direct employees on their payroll, including over 7,400 scientists. There is a clear division of responsibility among these entities. The government opened out the defence sector to foreign companies as well and these companies could own up to 26 per cent equity stake in any defence joint venture. (The FDI cap has been increased to 100 per cent by the Modi government, whereas, in the automatic route it is 74 %.)

The Govt of India has come out with a list of 101 defence related items which have been banned from imports. These items should be taken up for manufacture by the Private Sector under the aegis of an Empowered Committee.

The negative list of 101 items is a comprehensive one. It includes not just simple projects like water jet fast attack craft and offshore patrol vessel, but a host of complex weapons and platforms such as assault rifles, artillery guns, missile corvettes, attack helicopters, fighter and trainer aircraft and small transport planes. Among all the listed weapons and platforms, 69 items are banned for import from December 2020, 11 from December 2021, 4 from December 2020, 8 each from 2023 and 2024, and one (long range land attack cruise missile) from December 2025. The staggering timelines seem to be driven by the current developmental status of various projects being undertaken by the Defence Research and Development Organisation (DRDO), Defence Public Sector Undertakings (DPSUs), Ordnance Factory Board (OFB) and the private sector at large.

The opportunities for manufacturing would largely relate to these 101 items in the above list notably for assault rifles, ammunition, explosives and aviation sectors.

The defence sector worldwide has been responsible for many ground-breaking technological advances, from the internet and computers to drones and GPS. Over the years, western nations have invested heavily in R&D in order to keep one step ahead of the adversary and gain first -mover advantage. But today, a combination of military budget restrictions and the exponential growth of technology companies have left defence trailing the civilian world in terms of R&D. India’s spending on R&D in terms of percentage of GDP has been stagnant at 0.6 to 0.7 per cent in the last two decades — much lower than the US, China, South Korea and Israel, the Economic Survey said.

Consequently, defence organisations need to be attuned to emerging innovations emanating from outside the defence sector and embrace them as early as possible.

With the growing challenge of cyber warfare, defence organisations risk having shiny new platforms that are poorly connected and vulnerable to cyber-attack. The cyber arms race is here to stay. As everything becomes connected, the systems and devices may become more open to hacking; something that requires close attention. Most nations are investing heavily in cyber warfare capabilities from both a defensive and, in some cases, an offensive standpoint. Cyber defence should be one of the fundamentals of procurement, otherwise investments can be wasted.

United States Department of Defence exposed information stealing malware called “Slothful Media” which were involved in cyber attacks against India, Russia, and Ukraine. The US-Israeli attack through its Stuxnet-2010 disabled Iran’s nuclear facility. Today cyber attacks are a common occurrence especially in the private sector. The government therefore needs to invest in cyber security especially in areas of artificial intelligence. India has now announced to form a Defence Cyber Agency.

Certain skills are scarce; in the technology arena these are notably in skill sets such as data analysis, data science, artificial intelligence (AI), algorithms, modelling and simulation. Such talent may be less interested in long-term careers, so defence organisations must find new ways of accessing these vital resources, or risk falling behind. This requires new employment models for instance, episodic careers. Another challenge is that the rate of growth in salaries for technology top talent continues to diverge from public sector norms.

According to a study by KPMG, most organisations effectively exploit less than 25 percent of the data that already exists within the organisation. Artificial intelligence (AI) is making great strides, but it needs significant bandwidth to be able to operate on these workloads without degrading performance. 5G is set to release new waves of data, but also has the bandwidth to support the AI needed to make sense of it.

Gradually, the private sector has started to make inroads in the field of defence manufacturing. Hyundai Heavy Industries (HHI) of South Korea will work with Hindustan Shipyard Limited, Vizag to build warships in India. Currently, the time duration from the point of order to delivery takes around 6 years. With this collaboration, this gap is expected to fall to 2.5 years. The initial understanding was completed during PM Modi’s recent visit to South Korea. Another South Korean major, Samsung, has also agreed to build LNG tankers with Kochi Shipyard.

Bharat Forge has commenced defence projects for manufacture of Artillery guns, anti-tank missiles, armoured vehicles and aerospace components, Reliance has opened up a separate defence vertical for manufacture of helicopters, TATA advance systems is into C-130 Hercules aircraft in collaboration with Lockheed, Mahindra’s Defence Systems Limited is into Scorpio vehicles, Larsen and Toubro is investing in infra structure projects and transport canister for Brahmos missiles as well as designing India’s first nuclear powered submarine and Ashok Leyland is taking on Stallion vehicles.

Another decision made recently was that Goa shipyard will construct 12 minesweepers for the Indian navy at a cost of 1 billion USD. The Gurgaon based Sun Group, is in discussion with Russia, to manufacture 200 Kamov Ka 226 light helicopters in Punjab. The German and US defence ministers were in India recently to push sale of their products and there have been news reports that India will engage with them, only if there is a “Make in India” component in the deal. Reliance Infrastructure is in discussion with officials in Russia to explore opportunity to build nuclear submarines and stealth warships in India, along with other partners.

There is a huge scope for the private sector, considering India’s large and growing defence budget in general and the capital expenditure (most of which is spent on procurement of hardware) in particular. Assuming that nearly 80 per cent of the capital expenditure would be spent on capital procurement, the order of magnitude would be $300 billion. Much of India’s defence procurement budget is spent on imports. If the private sector can capture a part of what is imported, there is still a huge opportunity to look for.

In the early 1980s, we had phased manufacturing plans that were forcing Indian importers to indigenise over a period of five years. Unfortunately, when the economy started opening up we signed the WTO norms and local manufacturing took a back seat as it was easier and cost effective to import rather than manufacture locally. We need to reverse this, if we really want to focus on manufacturing and take it to the next level.

The Indian Defence Industries will have to adopt disruptive technologies to come out of this quagmire. The time of digitalisation has come. In times to come it will be all about vastly enhanced computing and communicating powers and adopting it to different applications in different forms. We need to adopt technologies such as robotics, artificial intelligence, big data analytics, and semi conductors and advance computing and hypersonic realms.

In the coming weeks, the impact on how we live, how we work, how we use technology will emerge more clearly. Institutions that reinvent themselves using insight and foresight will succeed. Online contactless commerce will reshape consumer behaviour. The world has now changed over. Adaptation will be the key.

Title Image Courtesy: Image provided by Author

Disclaimer: The views and opinions expressed by the author do not necessarily reflect the views of the Government of India and Defence Research and Studies